Top 10 Tips for Choosing the Best Flex PCB Board for Your Project

In the ever-evolving landscape of electronics, the importance of selecting the right components cannot be overstated. Among these, the flex PCB board stands out as a key player, providing unparalleled versatility and efficiency. As industry expert Dr. Emily Tran, a leading engineer in flexible circuit design, emphasizes, “A well-chosen flex PCB board can significantly enhance the performance and reliability of your project.” This insight highlights the critical nature of making informed decisions when integrating flexible printed circuit boards into modern electronic applications.

When embarking on a new project, understanding the specific requirements and constraints is essential. Factors such as size, shape, and thermal management capabilities need to be considered, as these elements can greatly influence the final outcome. The right flex PCB board not only accommodates complex designs but also fosters innovation by allowing for more compact and lightweight solutions. In the following sections, we will explore the top ten tips for choosing the best flex PCB board, ensuring your project achieves its intended goals while maximizing efficiency and performance.

Understanding the Basics of Flex PCB and Its Benefits

Flexible Printed Circuit Boards (Flex PCBs) are a remarkable innovation in electronic design, allowing for greater freedom in configurations and applications.

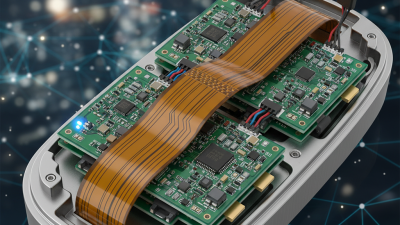

Unlike traditional rigid boards, flex PCBs are made from pliable materials that can bend, twist, and fold, making them ideal for compact and intricate spaces. This adaptability not only supports innovative designs but also leads to more efficient use of space within devices, enhancing overall functionality.

One of the key benefits of flex PCBs is their lightweight nature, which contributes significantly to weight reduction in electronic assemblies. This quality is particularly important in industries like aerospace, automotive, and consumer electronics, where every gram counts.

Furthermore, flex PCBs can endure vibrations and fluctuations, providing increased durability over rigid counterparts. This resilience ensures that they maintain performance under various conditions, ultimately extending the lifespan of the electronic devices they power.

Understanding these fundamental advantages helps engineers and designers make informed decisions when selecting components for their projects, paving the way for cutting-edge technological advancements.

Key Factors to Consider When Selecting a Flex PCB Board

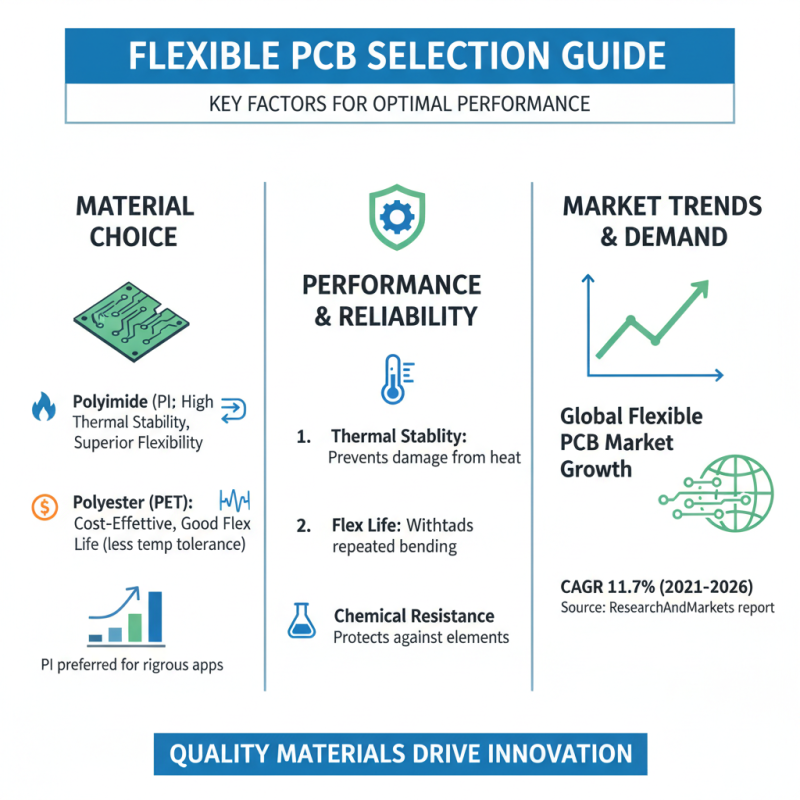

When selecting a flex PCB board for your project, several key factors come into play that can dramatically influence the performance and reliability of the final product. One of the primary considerations is the material used in the PCB construction. The most common materials include polyimide and polyester, with polyimide often being preferred for its superior thermal stability and flexibility. According to a report by ResearchAndMarkets, the global flexible printed circuit boards market is expected to grow at a CAGR of 11.7% from 2021 to 2026, underscoring the increasing demand for high-quality materials that can withstand rigorous applications.

Another crucial factor is the design complexity of the PCB. As technologies evolve, many industries are leveraging intricate designs to accommodate their specific project requirements. It’s essential to evaluate the number of layers, the overall dimensions, and the required bend radius. A recent study published in the Journal of Electronics Manufacturing emphasized that improper design choices can lead to failures in the field, highlighting the importance of collaborating closely with experienced engineers during the design phase. Additionally, understanding the environmental conditions the flex PCB board will face—such as exposure to moisture, temperature fluctuations, and physical stress—can inform material selection and overall design strategies, ensuring long-lasting performance in your application.

Evaluating Material Options for Optimal Flex PCB Performance

When selecting materials for flex PCB boards, it's crucial to consider the unique requirements of your project to ensure optimal performance and reliability. One key material option is polyimide, which offers excellent thermal stability and mechanical flexibility. This makes polyimide an ideal choice for applications that require bending and twisting without compromising the integrity of the circuit.

Another material to evaluate is polyester, known for its cost-effectiveness and ease of handling. While it may not match the thermal performance of polyimide, polyester can still provide satisfactory results in less demanding environments. When choosing the right material, consider the end-use conditions such as temperature ranges, stress factors, and environmental influences to make an informed decision.

Tip: Always assess the specific application requirements against the material properties to optimize PCB functionality. Additionally, conducting a small-scale prototype test can help identify potential issues before full-scale production. This method can save both time and resources in the long run while ensuring that the selected flex PCB meets all performance expectations.

Design Considerations for Flex PCB Layout and Configuration

When designing a flex PCB, layout and configuration are crucial factors that directly impact performance and manufacturability. A recent industry report from IPC suggests that nearly 70% of assembly defects in flexible circuitry can be traced back to improper layout choices. Therefore, engineers must prioritize optimal material selection and design for manufacturability (DFM) principles. Choosing the right materials, such as polyimide for its thermal and mechanical stability, can significantly enhance the board's reliability in various applications.

Another critical design consideration is the incorporation of bend ratios in the flex PCB layout. The standard bend radius is often set at 5 to 10 times the thickness of the PCB to prevent damage during operation. When designing a flex PCB, engineers must ensure that traces are routed carefully, avoiding tight bends that could induce stress fractures. Moreover, a study by Electronics Magazine indicates that over 60% of flex PCB failures occur at the flex zone. Employing strategies like reinforcing critical areas and using tapers on traces can lead to improved durability and performance, making a significant difference in the longevity of the final product.

Budgeting for Your Flex PCB Project: Costs and Savings Strategies

When budgeting for a flex PCB project, understanding the potential costs involved is crucial for effective financial planning. Flex PCBs often have a higher initial expense due to their advanced manufacturing processes and materials used compared to traditional rigid PCBs. Factors such as the complexity of the design, the quantity of boards needed, and the thickness of the materials can significantly influence the overall cost. Therefore, it’s essential to evaluate these variables carefully to prevent unexpected expenses and ensure the project stays within budget.

To maximize savings while still achieving high quality, consider several strategies. First, optimize your design by simplifying patterns and reducing the number of layers, which can greatly reduce manufacturing costs. Additionally, increasing the order volume can lead to discounts from manufacturers. It’s also wise to conduct thorough comparisons among different manufacturers, as pricing can vary significantly. Seeking out vendors that offer cost-effective solutions without compromising quality is beneficial. Furthermore, taking advantage of early design feedback can help identify potential issues that could lead to costly revisions later in the process, ensuring your flex PCB project remains financially sound.

Budgeting for Your Flex PCB Project: Costs and Savings Strategies

Related Posts

-

2025 Trends in Flexible Printed Circuit Boards: Innovations and Applications

-

Top 10 Circuit Board Design Tips for Beginners and Experts

-

The Future of PCB Manufacturing Innovations Transforming Electronics Industries

-

What is Rigid Flex Rigid PCB and How it Benefits Modern Electronics

-

What is Circuit Board Design and How to Get Started with It

-

Understanding the Latest Innovations in PCB Manufacturing for Modern Electronics